Creating an environmental chamber tailored to specific research or industrial needs can be a rewarding yet complex endeavor. This specialized equipment, crucial for simulating a wide range of environmental conditions, allows scientists, engineers, and product developers to test materials, components, and systems under controlled conditions.

This article aims to guide you through the intricate process of designing your own environmental chamber, emphasizing customization and innovation to meet your unique requirements.

Understanding the Basics

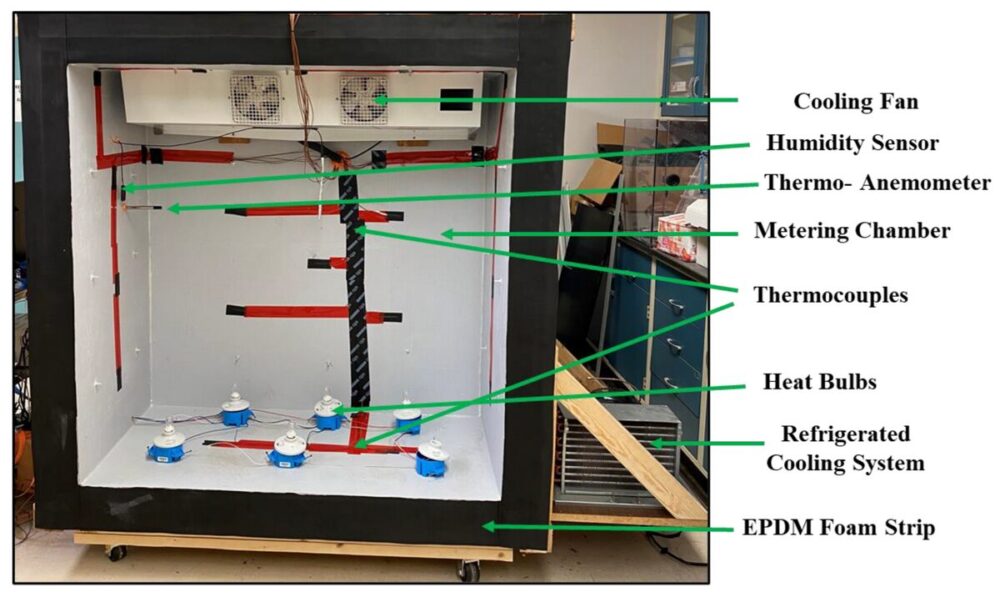

Source: mdpi.com

An environmental chamber, at its core, is an enclosure used to replicate environmental conditions. These conditions can range from extreme temperatures and humidity levels to atmospheric compositions and pressure variations.

The primary purpose is to observe the effects of these conditions on the subject matter, be it biological specimens, electronic components, or material samples.

Identifying Your Needs

The first step in designing an environmental test chamber is to precisely identify what you need from the equipment. Consider the range of conditions you aim to simulate, including temperature, humidity, light, pressure, and any other environmental factors relevant to your work. Also, contemplate the size of the items being tested, as this will influence the chamber’s dimensions.

Conceptual Design

Once you have a clear understanding of your requirements, the next step is to draft a conceptual design. This involves outlining the basic structure of the chamber, including its dimensions, insulation materials, and the type of control systems required to regulate environmental conditions.

It’s crucial at this stage to think about the future needs and potential modifications that could enhance the chamber’s utility.

Selecting Materials and Components

The choice of materials and components is critical in building an environmental chamber. Insulation materials must be capable of withstanding extreme temperatures and humidity levels without degrading. Similarly, the choice of sensors and controllers for regulating temperature, humidity, and other conditions must be accurate and reliable.

Customization for Specific Applications

Customization is key to designing an effective environmental chamber. This may involve integrating advanced sensor technology for more precise measurements, incorporating specialized lighting systems for plant growth studies, or designing custom fixtures to hold experimental samples.

The goal is to adapt the chamber to the specific needs of your work, rather than trying to adjust your work to fit the limitations of a standard chamber.

Innovative Features

Innovation can significantly enhance the functionality and efficiency of an environmental chamber. This could include developing new methods for more rapid or uniform temperature changes, implementing energy-saving features, or integrating software that allows for more sophisticated control and data analysis.

Control Systems

Source: testingandsimulation.com

The heart of any environmental chamber is its control system. This system must be capable of accurately monitoring and adjusting the internal conditions of the chamber. Advanced control systems can be programmed to simulate complex environmental patterns or sequences, providing a more dynamic range of testing conditions.

Safety Considerations

Safety should be a paramount concern in the design of an environmental chamber. This includes not only the safety of the operators but also the protection of the samples and the integrity of the research.

Safety features might include fail-safes for temperature and humidity control, alarms for out-of-spec conditions, and proper ventilation to handle any emissions or off-gassing from the chamber.

Testing and Calibration

Before an environmental chamber can be used for its intended purpose, it must be rigorously tested and calibrated. This ensures that it can accurately replicate the desired conditions. Calibration often involves using certified reference materials and comparison with known standards to adjust the chamber’s sensors and controls.

Maintenance and Upkeep

Maintaining an environmental chamber is crucial to ensure its longevity and reliability. Regular maintenance tasks might include cleaning, sensor calibration, and inspection of components for wear and tear. Proper upkeep not only extends the life of the chamber but also ensures consistent and reliable results.

Advanced Applications

As technology advances, so too do the possibilities for environmental chamber applications. From aerospace and automotive testing to climate change research and beyond, the potential uses are vast and varied.

Designing your chamber with future applications in mind can make it a versatile tool for a wide range of scientific and industrial tasks.

Collaboration and Expert Consultation

Designing an environmental chamber is a complex task that often benefits from collaboration and expert consultation. Engaging with specialists in fields like HVAC (heating, ventilation, and air conditioning), control systems, and material science can provide valuable insights and help avoid common pitfalls.

Ethical and Environmental Considerations

Source: russells-tech.com

Ethical and environmental considerations are increasingly important in scientific and industrial equipment design. This includes using sustainable materials, minimizing energy consumption, and ensuring that the chamber’s use complies with ethical standards, particularly in biological and medical research.

Documentation and Training

Comprehensive documentation is essential for any custom-designed equipment. This includes detailed operating instructions, maintenance schedules, and troubleshooting guides. Additionally, providing thorough training for all users of the environmental chamber is crucial to ensure safe and effective operation.

Integrating Technology for Enhanced Functionality

In the age of rapid technological advancement, integrating cutting-edge technology into your environmental chamber can greatly enhance its functionality.

This could involve incorporating IoT (Internet of Things) capabilities for remote monitoring and control, using AI (Artificial Intelligence) for predictive maintenance and anomaly detection, or employing advanced data analytics for deeper insights into test results.

The integration of such technologies not only improves the efficiency and effectiveness of the chamber but also opens up new avenues for research and development.

Sustainability and Eco-Friendliness

As global awareness of environmental issues grows, designing your environmental chamber with sustainability in mind becomes increasingly important. This involves selecting eco-friendly materials, optimizing energy use, and considering the lifecycle impact of the chamber.

Sustainable design not only reduces the environmental footprint of your research or testing activities but also aligns with the growing emphasis on green practices in science and industry.

Future-Proofing

Finally, it’s wise to consider the future when designing your environmental chamber. This might involve including modular components that can be upgraded or replaced, designing with expandability in mind, or incorporating smart technology that can adapt to new research needs.

Closing Thoughts

Source: crossco.com

Designing your own environmental chamber is an intricate task that involves balancing numerous factors, from meeting specific environmental conditions to ensuring the system’s safety and reliability.

By prioritizing customization and innovation, and embracing collaboration with experts, your chamber can be tailored to your exact needs. Furthermore, by integrating advanced technologies and emphasizing sustainability, you not only enhance the chamber’s functionality but also contribute to the advancement of eco-friendly research practices.

The ultimate aim is to create a versatile, efficient, and future-proof tool that not only serves your current requirements but is also adaptable to the evolving landscape of scientific and industrial exploration.