If you are someone who works in the heavy machine industry and, to be specific, you will know the importance of an encoder in the control department. It is the eyes and ears of the control department. In simple words, an encoder is a small sensor that keeps an eye on the working of the machinery. It ensures that everything is going as per the plan. In companies that use heavy machinery or have a smooth production line going on, an encoder gives constant output on the working of the machinery. So, if something is not as per the program, the encoder will get a signal to the control department immediately, and they can rectify the problem.

Given its importance in the industry, it is crucial that the encoder is of premium quality and technology. So, if you have been given the task to find a reliable Encoder Products Company for your organization or machinery, a lot lies on your shoulder. Here is a quick review of what an encoder is before we head towards a few tips for finding the right company.

What is an encoder?

An encoder is found in all types of machines in every industry responsible for motion feedback and control. The primary purpose of the encoder is to provide feedback that either the ongoing job is done correctly or not. It is like a sensing device that collects data from different sensors and provides feedback to the control system. It provides feedback for several functions such as direction, speed, count, or position. The control system then uses the data from the encoder to adjust different functions according to the job requirement.

What does an encoder do?

Encoders work based on signal generation, and these signals can be different, such as mechanical, electrical, magnetic, or optic. However, the optic is most commonly used in encoders where feedback is provided due to the light interruption.

There are generally two types of encoders, namely rotary and linear. The difference between the two is that the rotary encoder reacts to rotating motion; however linear encoder reacts to linear motion. The complete package of linear encoder consists of a sensor or transducer coupled with a scale to give position.

The sensor has the ability to read the position of the scale, which is then converted into an electrical signal to feed the control system. The programming is already done in the controller, which reads or decodes the signal from the encoder and takes necessary action. In contrast, the rotary encoder is an electro-mechanical device consisting of a sensor or transducer and a round disc with a scale that converts the circular motion into an electrical signal fed to the controller.

Types of Encoder signals:

There are two types of signals produced by the encoder, i.e., absolute or incremental. Incremental signals only refer to the change in position but do not provide an exact position. However, an absolute signal provides information that position is changed, and it also provided information that how much position is changed. In other words, it provides incremental position as well as the position of the encoder.

How to choose the Reliable Encoder Products Company

Here are a few tips that you should keep in mind when looking for a reliable encoder.

1. What are you using it for?

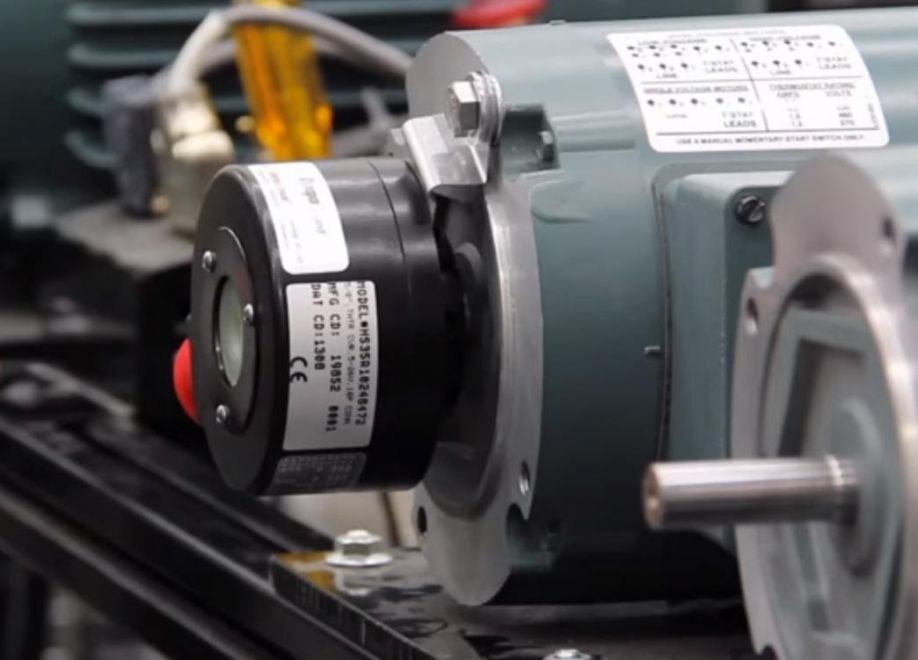

Source: manufacturingtomorrow.com

Before starting to hunt for a reliable encoder products company, the first thing to keep in mind is to create a clear map of what you are looking for? For this, you need a detailed technical understanding of the machine and process for which you are looking for the encoder. So, ask a few questions like whether you require a digital or an analog output? Whether the machine application is linear or rotary? Etc. once you have a precise detail on the requirements, your work is cut in half.

2. What types do they offer?

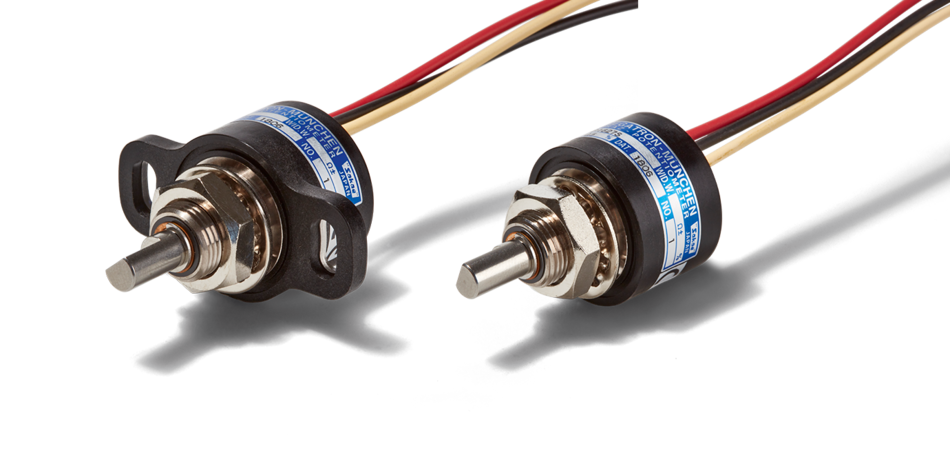

Source: intechauto.in

Like we have mentioned earlier, encodes come in different types. The main two types are entirely different from each other. Although the output is the same, it’s the process that is different. So, when looking for a company, take some time to analyze the types they are offering, whether the company specializes in providing digital encoders or analog.

There is a vast range of different encoders available in the market that can be used for different applications. It is necessary to look deeply into the technology they are offering before randomly selecting one. After all, what they are offering should be in alignment with what you require. Otherwise, it will be a waste of time and money.

3. Testimonials

Source: turck.de

Several companies offer testimonials for their content and satisfied clients. Testimonials can tell you a lot about the quality the company is offering. So, it is better to invest some time looking into the comments and reviews of the clients. You can also ask the company to provide you information about their happy clients to talk to them in private and know about how content they are. It can make your decision easier; furthermore, you can also look for word of mouth.

4. Look at their catalog

Almost all encoder companies offer catalogs. Having a catalog makes your work so much easier. You don’t have to talk to their representatives every time you have a question in mind. The primary purpose of a catalog is to provide all the relevant information regarding a product. So, it is like your guide. You can look into their features, specifications, and other technical information via the catalogs.

Finding the right type of encoder can be one thing but selecting the right encoder products company is an entirely different experience. It requires knowledge, information, and the power to making the right decision. As overwhelming as it may seem, things can be in your favor when you have a clear plan in your mind. So, keep in mind the tips mentioned above and find a reliable company!